and on the left side on my sump you can see he cut my teeth down on my baffles and broke 2 of the teeth off.:12: good thing this is one of my sumps and I wasn't doing one for someone else I would of killed him.......

so I asked him what the hell did you do??? he said it kept jumping around on him???? I said even after you put the router guide on the Dremel, he said oh that's what the black thing in your case is for??????

he used my pencil extention with the router bit in it to cut the teeth.

oh well it don't look pretty any more but it should do the trick.

Okey enough venting...LOL.

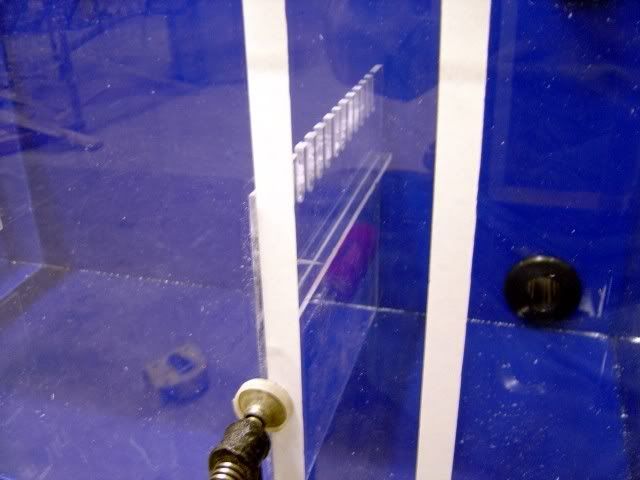

well to start out I got my baffle cut and teeth cut in I used my double 3/8th fluted router bit on this baffle. and added a shelf bracket 2" below my teeth so I could add a egg crate shelf so if I waned to run carbon or filter media.

in my finished photo you will see how the braces for my Egg crate shelf was done.

in these shots I'll show you how I made my probe bracket.

I'll be running a PH,Salinity, and calcium monitor, so I made a 3 hole bracket.

first I drilled my holes I used High carb drill bits at a medium speed, to fast you run the risk of cracking or chipping your Acrylic same with to low of a speed. if you don't have a drill press make sure you use acrylic drill bits. it will save you a lot of head aches.